To efficiently service a variety of needs, Microform Precision offers many different methods of cutting. With laser cutting, we can offer fast cutting times and high precision. We are also one of the few manufacturers in Northern California to offer fiber optic laser cutting at scale. Water jet cutting allows us to handle material types and thicknesses that aren’t a best fit for laser cutting. With turret punching, we can offer a low cost approach for high volume runs. And with saw cutting, with can take on jobs using non-sheet materials such as tubing and rod. Click the links below to read more detailed descriptions of each method, including the equipment we use, and the tolerances we can hold.

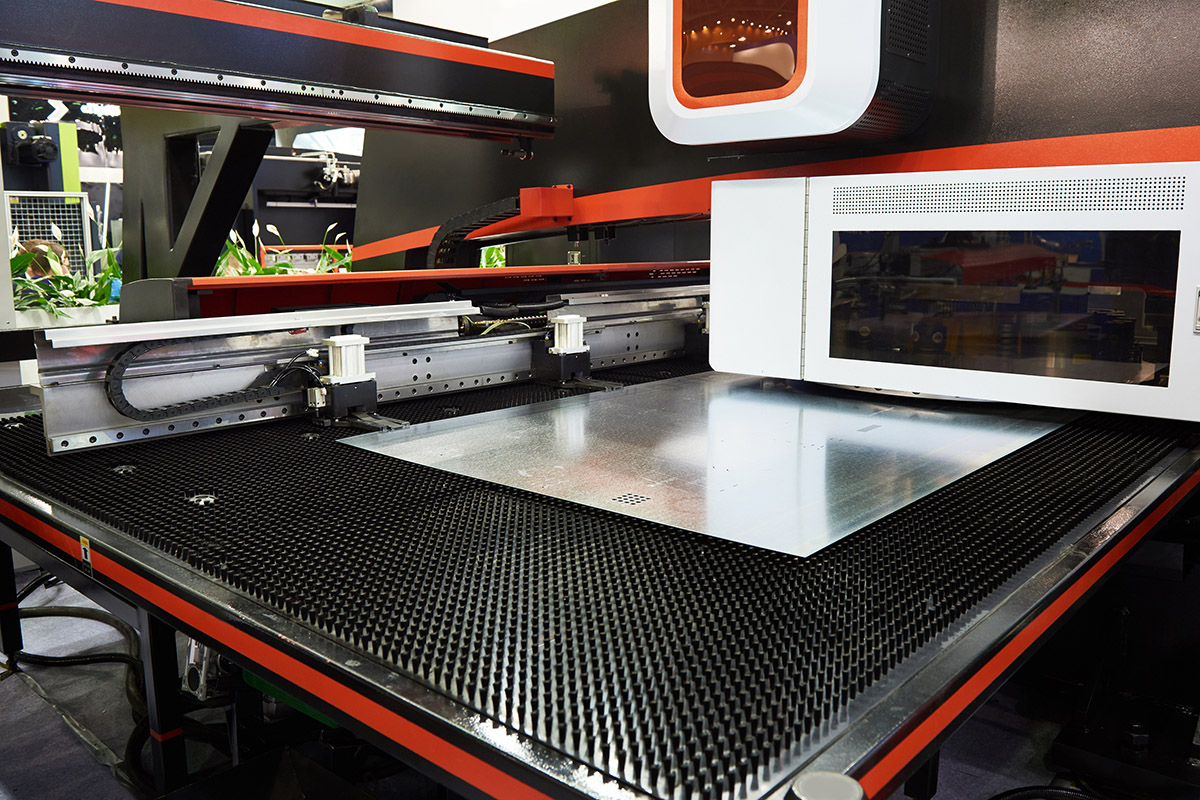

Laser Cutting

Laser cutting is well suited for mild steel (including pre-plated steels like galvanized steel), stainless steel, aluminum. Brass and copper can be handled by fiber optic laser cutting.

Waterjet Cutting

Need to cut thicker materials? Waterjet cutting may be the answer. Waterjet cutting eliminates heat affected zones (HAZ), so the intrinsic properties of the materials are unaffected.

CNC Turret Punching

Turret punching is a cost effective option for high quantity jobs with relatively simple profiles. A turret punching press allows for stamped features such as louvers, card guides, lances, electrical knockouts, and dimples.

Saw Cutting

Saw cutting is useful for cutting metal in forms other than a sheet. Saw cutting works well for cutting tubes, bars, and rods. Materials may include stainless steel, aluminum, copper, titanium, or composite materials.