Microform Precision is a full service precision sheet metal manufacturer offering turnkey solutions to most sheet metal needs. Our services begin with customer support and engineering, continuing with manufacturing and fabrication processes like cutting, bending, welding, powder coating and silk screening, to name a few. Almost all of our services are provided in-house. We have close relationships with machine shops and plating shops to cover the few remaining gaps you may need to complete your project.

Following is a list of the major sheet metal fabrication services that we offer. If you need something not listed here, don’t hesitate to inquire — we can help.

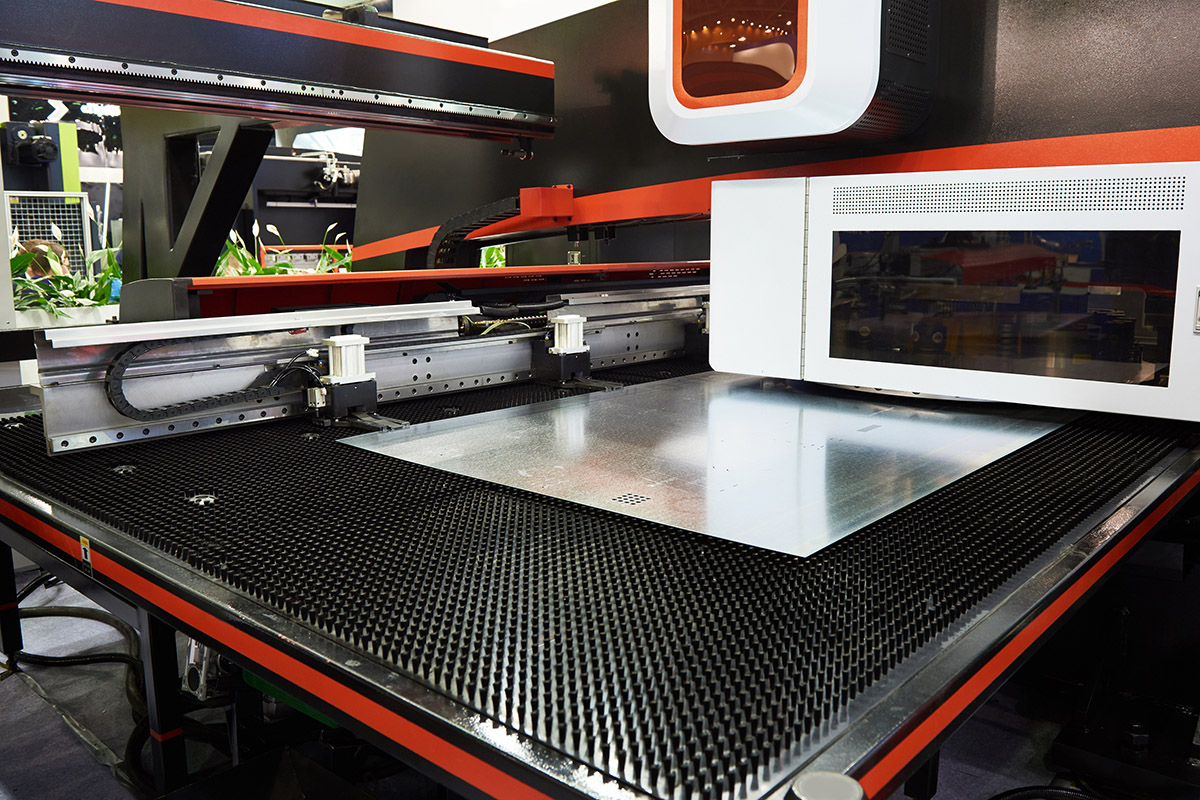

Laser Cutting

Laser cutting is well suited for mild steel (including pre-plated steels like galvanized steel), stainless steel, aluminum. Brass and copper can be handled by fiber optic laser cutting.

CNC Forming

CNC forming is the process of turning sheet metal into three-dimensional parts by exerting applied force. Forming may processes like press braking or power rolling.

Welding

Microform Precision provides welding and metal fabrication for Sacramento and Northern California. MIG, TIG, and spot welding available.

Waterjet Cutting

Need to cut thicker materials? Waterjet cutting may be the answer. Waterjet cutting eliminates heat affected zones (HAZ), so the intrinsic properties of the materials are unaffected.

CNC Turret Punching

Turret punching is a cost effective option for high quantity jobs with relatively simple profiles. A turret punching press allows for stamped features such as louvers, card guides, lances, electrical knockouts, and dimples.

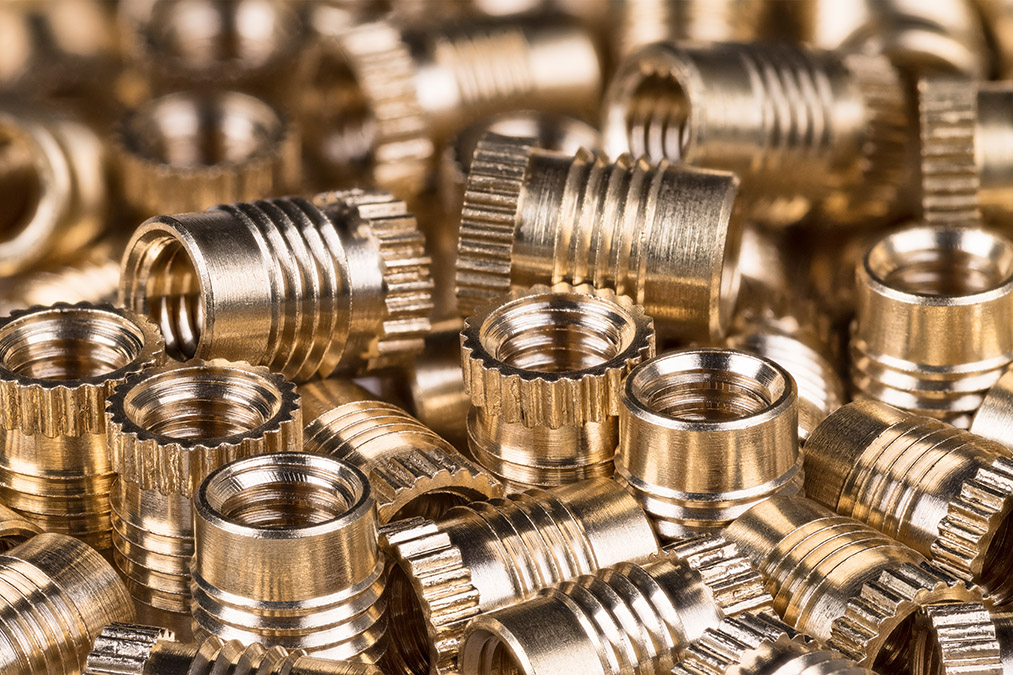

Hardware Insertion

Microform Precision can insert fasteners, self-clinching studs, standoffs, or other hardware into your sheet metal fabrication projects.

Saw Cutting

Saw cutting is useful for cutting metal in forms other than a sheet. Saw cutting works well for cutting tubes, bars, and rods. Materials may include stainless steel, aluminum, copper, titanium, or composite materials.

Powder Coating

Powder coating can be applied in a wide variety of colors and textures. Metal parts, appliances, structures, and machinery are commonly powder coated. We do all our powder coating in-house.

Industrial Screen Printing

Industrial screen printing is a process for adding graphic detail to a surface, usually by laying down a precise, measurable deposit of ink on a substrate.

Metal Graining

Line graining, or linear graining, is the process of adding a uniform surface finish to sheet metal parts. This is done by running the metal through a belt grinder.

Delivery Routes in Sacramento and the Bay Area

Microform Precision has delivery routes to the Sacramento metro area five days a week, and regular delivery routes to the Bay Area, Sierra Foothills, and North Sacramento Valley each week.