Our Flow Mach2 4020b waterjet cutting machine can cut most materials up to 4″ thick.

What is Waterjet Cutting?

Waterjet cutting is a process sometimes used in the fabrication and manufacturing of machinery and other parts. In waterjet cutting, a high-velocity stream of water, or water mixed with abrasive, cuts through a material, like plastic, glass, steel, or other metals.

CNC waterjet cutting is used in a diverse number of industries from mining to aerospace, and is essential for operations such as cutting, carving, shaping, and reaming.

Advantages of Waterjet Cutting

Waterjet cutting can compliment laser cutting services. Materials that are too thick, or not conducive for laser cutting often fit well with waterjet cutting.

Another advantage is waterjet cutting produces no heat affected zones (HAZ). This means the material can be cut without affecting its intrinsic properties, avoiding warping or distortion around the cutting edge.

Our waterjet cutting can cut steel and other metals up to 4″ thick. If your application requires cutting thicker materials, waterjet cutting may be the solution.

Waterjet cutting usually has less striations or burrs than some other forms of CNC cutting.

Considerations for Waterjet Cutting

- Materials will be at least partially submerged in water during the cutting process. Materials that would be damaged by exposure to water should not be cut by waterjet.

- Etchings may be left around cut outs, particularly in soft materials such as aluminum, from the spray. This may be cosmetically undesirable in some applications.

- Thicker materials will often have some degree of taper to the cut. This taper can be reduced (although perhaps not eliminated) by running at lower speeds. The trade off is a longer run time and higher cost.

- Due to changes in the regulatory environment, Microform Precision no longer offers water jet cutting services for materials with high copper or chromium content. This most notably eliminates copper and stainless steel from the material types that we water jet cut. We apologize for the inconvenience but still offer laser cutting or punching for most metals, including stainless steel and copper, assuming dimensional compatibility.

Waterjet Cutting Tolerances

| Feature Location | +/- 0.005″ |

Our Waterjet Cutting Equipment

We have a Flow Mach2 4020b, with 60k PSI pressure. This waterjet is capable of cutting most materials up to 4″ thick.

| Make | Model | Power | Max Sheet Size | Applications |

|---|---|---|---|---|

| Flow | Mach 2 4020b | 60000 PSI | 72″ x 156″ | Can cut most materials up to 4″ thick. |

How Does Waterjet Cutting Work?

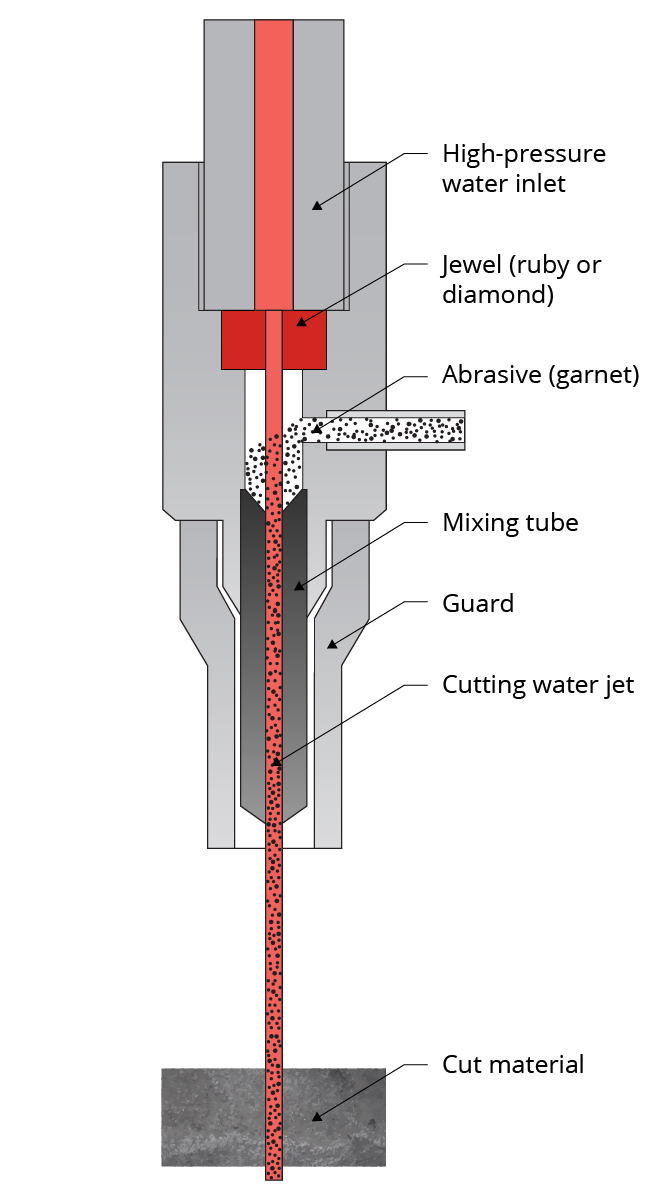

There are two different terms you need to know: abrasive jet cutting, and water-only cutting or pure waterjet cutting. They work the same way, with only one difference. In abrasive jet cutting, an abrasive (like garnet) is mixed with the water before cutting the material surface. Pure waterjet cutting is a hair-thin highly pressurized stream of only water, without abrasives.

Here’s what happens at a mechanical level. Water comes in through a high-pressure inlet, usually an outside high-pressure pump. (The regular tap will not supply sufficient pressure). If abrasive is being added (if you are cutting metal), that happens in the mixing tube. This mixture of abrasive and water is then forced through the nozzle, and the stream of water, or abrasive water cuts through the material.

The material being cut is usually submerged in water. This is to reduce noise and splashing.

The cutting heads on waterjet cutting machines usually rotate on multiple axis. This allows for angled, complex cuts.

Brief History of Waterjet Cutting

Waterjet cutting for soft materials, like paper and rubber, was pioneered in the 1930s. In 1958, the first waterjet cutting for hard materials, like steel and other metals, were introduced. In the 1970s, the Bendix Corporation introduced the idea of using nozzles made of high Mohs hardness minerals.

Around this same time, increasingly high PSI machines were designed, and Flow Industries discovered treating the water beforehand would lead to increased life of the nozzle.

Today, machine shops and manufacturers use waterjet cutting to make clean, precise cuts in a wide variety of materials such as glass, plastic, acrylic, stainless steel, aluminum, titanium and other metals.