What is CNC Turret Punching?

CNC turret punching is a process in sheet metal manufacturing where shapes are cut by a punch press out of a piece of metal. The CNC turret punch is programmed to move the sheet of metal into position along a x-y axis, so the punching arm cuts out the form. Different tools are available in the turret, so a variety of shapes and forms can be punched out from the sheet.

Applications for CNC Turret Punching

Turret punching is a cost effective option for high quantity jobs with relatively simple profiles. A turret punching press allows for stamped features such as louvers, card guides, lances, electrical knockouts, and dimples.

What Are Considerations for Turret Punching?

Hard tooling with a turret punch press requires a longer set up time than laser cutting or waterjet cutting, so smaller quantity runs may not be cost effective. For prototyping, waterjet cutting or laser cutting are usually a better choice.

The cutting paths may be limited by the tooling available. Complex shapes may need to be cut by a process called nibbling which may leave a segmented edge as opposed to a smooth line.

Nibbling is a process most commonly done by a turret punch where a cut line is achieved by a rapid series of small hits.

If all the elements to be formed are the same shape and diameter, turret punching can be more efficient than other forms of cutting, on larger production runs.

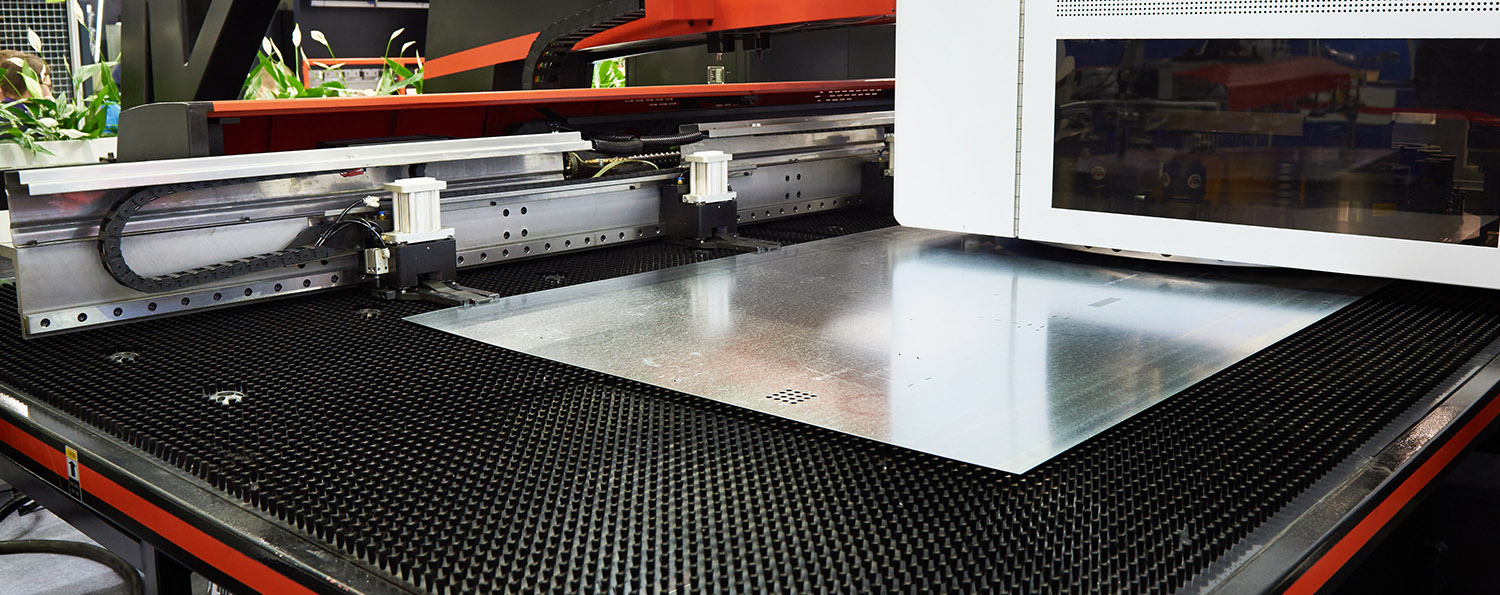

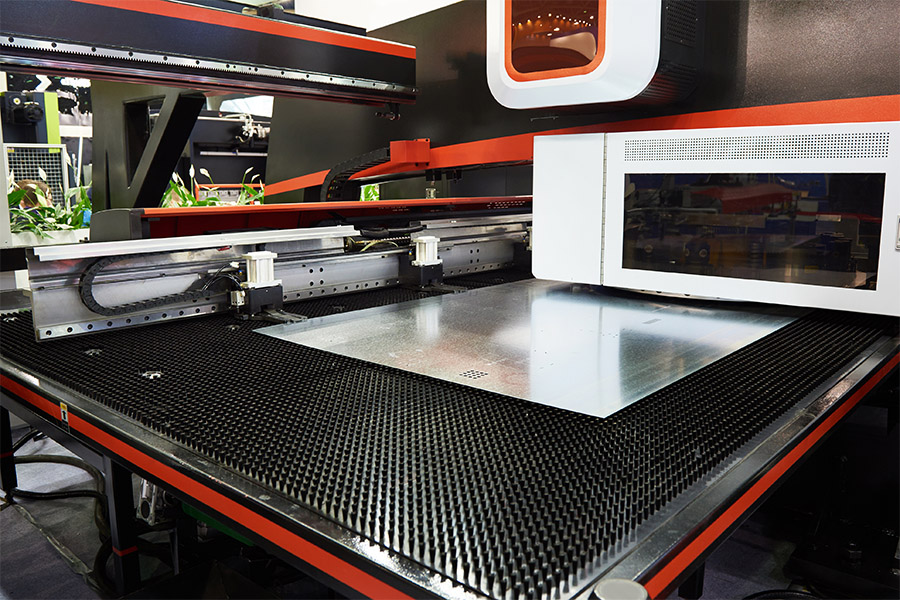

Our CNC Turret Punching Equipment

| Make | Model | Max Sheet Size | Max Hole Diameter | Max Material Thickness |

|---|---|---|---|---|

| Amada | Vipros 358 King II | 44*” x 70″ | 4.5″ | 0.125″ |

* Actual table size is 48″ x 70″ but approximately 4″ of the width is needed for tooling, clamps and border material. Some parts may lend themselves to smaller borders in which case a maximum length exceeding 44″ may be possible.

Our CNC turret punching press is an Amada 358 King II. This particular model has 58 tool stations in a turret, that can be rotated to bring a designated tool to the punching position. A simple shape, like a circle, hexagon, or rectangle can be cut directly from the sheet. More complex shapes may be cut by making additional square or rounded cuts around the perimeter of the original hole.